The field of electricity apparatus

Product introduction

Transformer FAQ

We will answer common question about transformer.

Please refer before question laying upon.

It can detect the damage and abnormality of transformer early by carrying out daily life or periodical maintenance, check and driving monitoring, but is useful for improvement in reliability of power supply by updating at time when it is more appropriate about accessories.

■Role of transformer accessories

1. We deal before developing into big accident disorder and prevent you from affecting power supply.

2. We minimize the damage of transformer and facilitate restoration.

Generally update time of the transformer body was 20-30 years and improved reliability of transformer even more and gathered up as our suggestion economically from maintenance, the check top about update recommendation time of accessories thought to be advantage.

(person wanting detailed material, please refer to Japan Electrical Manufacturers' Association technical data JEM-TR197)

| Exchange recommendation time table of parts attached to transformer | ||||

| Importance rank | Accessories name | Update Recommendation time |

Exchange The days |

Of blackout Necessity or not |

|---|---|---|---|---|

| A-1 When it detects abnormality of the body early, and trouble occurs, influence greatly extends to the body performance |

Oil thermometer | Ten years | 1st | The pivot |

| Pressure discharge device | Ten years | 1st | The pivot | |

| Internal trouble detector (pitorire, buffuhorutsurire, shock pressure relay) | Ten years | 1st | The pivot | |

| A-2 When trouble occurs, influence greatly extends to the body performance |

Bushing | 15 years | 2nd | The pivot |

| Refrigerator (own cold expression radiator, water-cooled expression air conditioner, yunittoku-ra) | 15 years | 3-5 days | The pivot | |

| Supplying oil pump | 15 years | 2nd | The pivot | |

| Cooling fan | 15 years | 1st | The pivot | |

| B Even if trouble occurs, there is relatively little influence of the body |

Dial oil gauge | 15 years | 2nd | The pivot |

| Gas detection relay | 15 years | 1st | The pivot | |

| Oil style direction indicator | 15 years | 1st | The pivot | |

| Meter to connect | 15 years | 2nd | The pivot | |

| Rubber film for konsabeta | 15 years | 1st | The pivot | |

| Moisture absorption respiratory organs | 15 years | 2nd | No | |

| Valves | 15 years | 4th | The pivot | |

| Differential pressure, running water, leak relay (only as for the water-cooled expression air conditioner) | 15 years | 1-2 days | Only as for the running water, it is the pivot | |

| C Main parts of accessories |

Bearing (no refueling form) | Three years | 1st | The pivot |

| Bearing (refueling form) | Ten years | 1st | The pivot | |

| Gasket (nitrile rubber) | 15 years | Use place ・We stop at point | The pivot | |

| Gasket (cork synthetic rubber) | Ten years | The pivot | ||

We maintain including transformer made in other companies from supervoltage transformer to dry process small capacity transformer as manufacturer specialized in transformer.

Our company develops low loss form transformer that planned electricity loss reduction and suggests total cost reduction by replacing with existing article.

■Loss of transformer

[no load loss]

Loss (it is loss of firm resolution and is also known as iron loss) to occur in excitation (applying) state to quantity of load irrelatively

[load loss]

Loss (also known as copper loss) to depend on electric current (load) which is mainly called off to winding

■It is way of thinking to becoming purpose of use of transformer and low loss

[when used as daytime factory load]

We recommend that we reduce loss in night light load.

We reduce no load loss including kokoritsu*sokoban and amorphous firm resolution transformer in conventional 30-70%.

[when we use to the full regardless of the night and day]

We recommend general efficiency form transformer that raised efficiency in high load band.

We mainly reduce one-day total loss by reducing winding loss (copper loss).

Our company plans 10% or more of loss decreases of that of the conventional company products by transformer having 80% or more of mean load factor.

■Calculation method of consumption loss

Loss (W) = no load loss (Wi) +k X k X load loss (Wc) of transformer

k: Transformer load factor (load factor (%)/100)

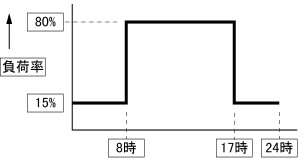

In the case of the following factory load pattern, electricity consumption loss of transformer per day becomes next.

No load loss = 24 X Wi

Load loss = 0.8 X 0.8 X Wc X 9+0.15 X 0.15 X Wc X 15

Is disadvantageous, and, as for our low loss form transformer, load is disadvantageous no load more than 20% (30% of standard values); of 10% or more (15% of standard values) fall low.

| Amorphous transformer/kei sokobanhenoshikishogenhikaku (transformer 20kVA with 6kV single phase oil) | ||

| Amorphous transformer | kei sokobanhenoshiki | |

| Dimensions W X D X H (mm) | 590 X 560 X 755 | 565 X 535 X 785 |

| Weight (kg) | 174 | 142 |

| No load loss (W) | 17 | 60 |

| Minus number loss (W) | 305 | 305 |